Energy Recovery from Wastewater

The water temperature in the various treatment stages plays an important role in the effective treatment of wastewater streams. As specialists in the treatment of process, industrial and wastewater, it is therefore an important basis for us, in addition to the wastewater volumes and their composition, for the planning and optimization of your wastewater engineering plant.

For example, partial streams that are too cold are a problem especially for anaerobic reactors – such as UASB (Upstream Anaerobic Sludge Blanket), EGSB (Expanded Granular Sludge Blanket) or IC (Internal Circulation) – because the bacteria depend on a minimum temperature for their metabolism. If the water enters the biological treatment stage too warm, the biomass may be damaged.

Social Relevance of Wastewater Cooling

In addition to the efficiency of their treatment, operators of wastewater treatment plants also have an eye on the social aspects of the water flows. To protect the adjacent waters and the organisms living in them, there are public regulations on what temperatures must be present during direct discharge. As a rule, the lower and upper water authorities determine on a case-specific basis what temperatures must be maintained. In Dresden, for example, there is an upper limit of 35 °C.

Another important aspect is the development of odors due to warm streams in the sewer system. Depending on the outside temperature, this phenomenon can be intensified and cause a nuisance to residents.

Energy from Wastewater with our self-cleaning Heat Exchanger E‑Plate

In the past, cooling towers and falling film coolers were a tried and tested means of cooling process water. But why give away the precious heat energy? Using a wastewater heat exchanger such as a rotary or plate heat exchanger, wastewater can be cooled while increasing the overall energy and performance efficiency of the plant. Maintenance-intensive solutions such as spiral heat exchangers have now been replaced by self-cleaning systems.

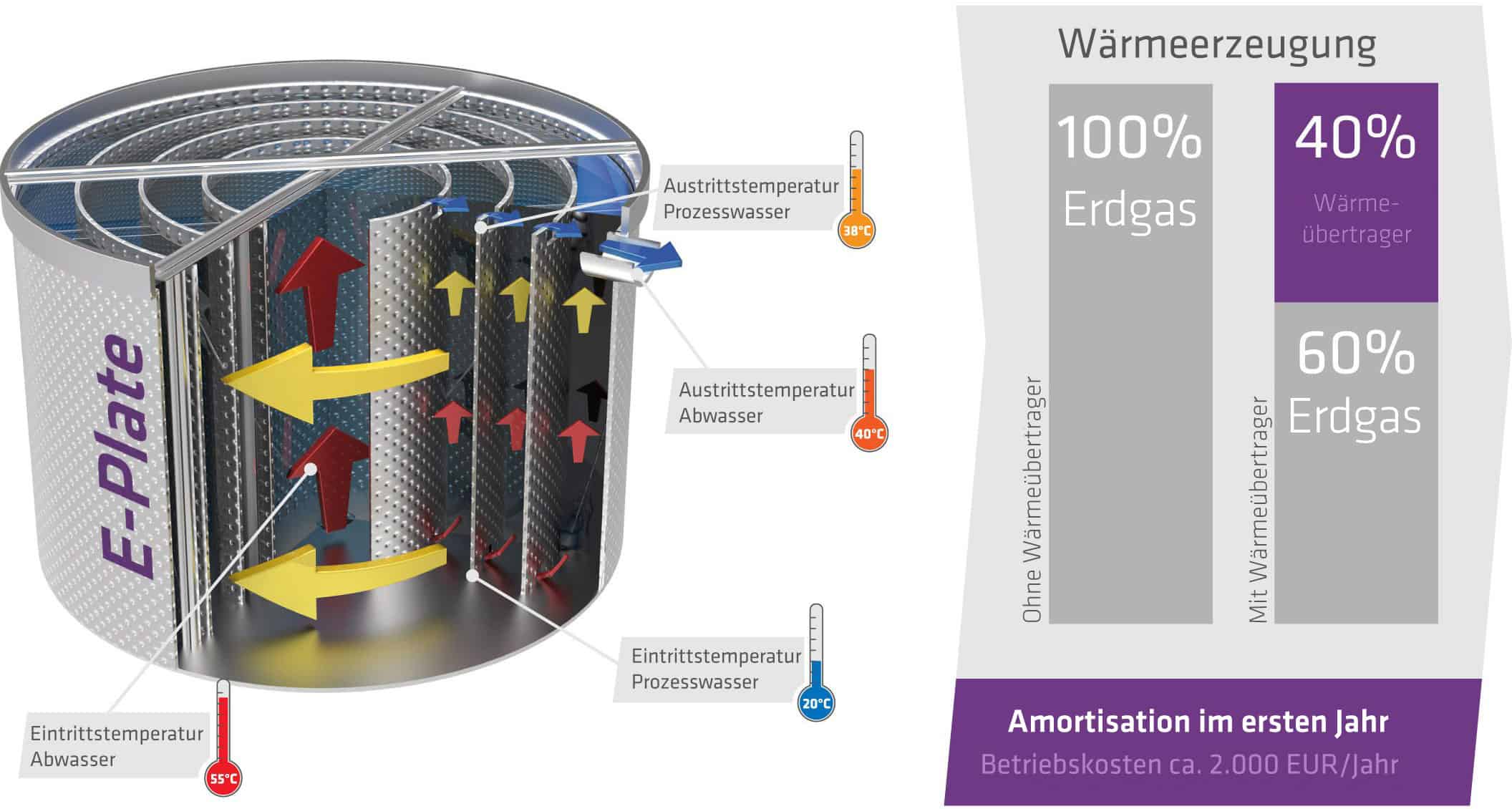

One example of this is our E‑Plate wastewater heat exchanger. Thanks to its optimized brush system, it cleans itself. It is therefore also suitable for heavily polluted wastewater. The continuously rotating brush system reduces fouling to a minimum and also ensures a high flow rate. This significantly increases the performance of the heat exchanger. By means of additional rotary movements of the brushes, the wastewater is brought into a spiral circulation, which achieves the effect of a countercurrent heat exchanger. Due to this design principle, it can be installed in the outlet of existing wastewater treatment plants without the use of additional booster pumps and does not require complex measurement and control technology.

The use of our E‑Plate wastewater heat exchanger can be incorporated into the design of your new wastewater treatment plant from the outset, as well as installed retrospectively to optimize existing wastewater plants. Our engineers will be happy to advise you on how to make the entire plant more energy and performance efficient by maximizing the efficiency of wastewater heat recovery.

YouTube is a service of YouTube LLC, a subsidiary of Google Inc, USA. You can find more information on data processing through this in our privacy policy. If you would like to watch this video, you also consent — revocable at any time — to the transfer of your data to the USA and the associated data processing in accordance with Art. 49 (1) a) DSGVO.

Practical example of the use of an E‑Plate Wastewater Heat Exchanger

The infographic takes the example of a paper mill. The process water supplied at the start of production is too cold at 12 °C and must be heated. At the end of the process, the wastewater has a temperature of 55 °C and is thus too warm for the installed biological wastewater treatment. The wastewater treatment plant would no longer function in this way, as the microorganisms would die off. In addition, there is an upper temperature limit of 30 °C set by the authorities for the discharge of wastewater.

It is not only paper mills that have problems with the water temperature at the outlet. Such a system is also worthwhile, for example, for operators of biogas plants, foundries and hardening plants, dye works, large laundries or for the food industry. By using the E‑Plate heat exchanger, the factory can save 40% of the natural gas previously required. The investment thus pays for itself in the first year.

Your contact person for all questions about energy recovery from wastewater

Florian Axt

Sales Engineer Water Treatment