Reliable and Safe Exhaust Gas and Water Treatment for the Solar Industry

Different gases are released during the production of solar cells. Our compact and efficient off-gas systems combine safe and reliable scrubbing and burning operations in the tightest of spaces. Aware that off-gas cleaning is crucial to the safety of the manufacturing process, we develop and manufacture burner/scrubber disposal solutions and electrostatic filters for off-gas flows up to 5,000 m³/h.

Our customers in the solar industry benefit from our strong technical understanding of the production processes for thin film silicon modules and crystalline cells, especially for CVD, TCO and drying processes.

In principle, DAS plants can treat condensable, combustible, corrosive, reactive, toxic and/or pyrophoric waste gases (e.g. silanes, silane organics, terpineols, hydrogen, ammonia or hydrogen halides) as well as fine dusts.

Experts from DAS Environmental Expert are not only available for planning the initial equipment, but also help with optimization and cost reduction in the running process. Learn more by reading our case study on cost reduction in a silicon thin film production line.

Point-Of-Use Exhaust Gas & Wastewater Treatment from DAS EE for the Solar Industry

Insight into our product portfolio:

- Exhaust gas cleaning systems

- Removal of condensable organic compounds (VOC’s)

- Reduction of particulate matter emissions

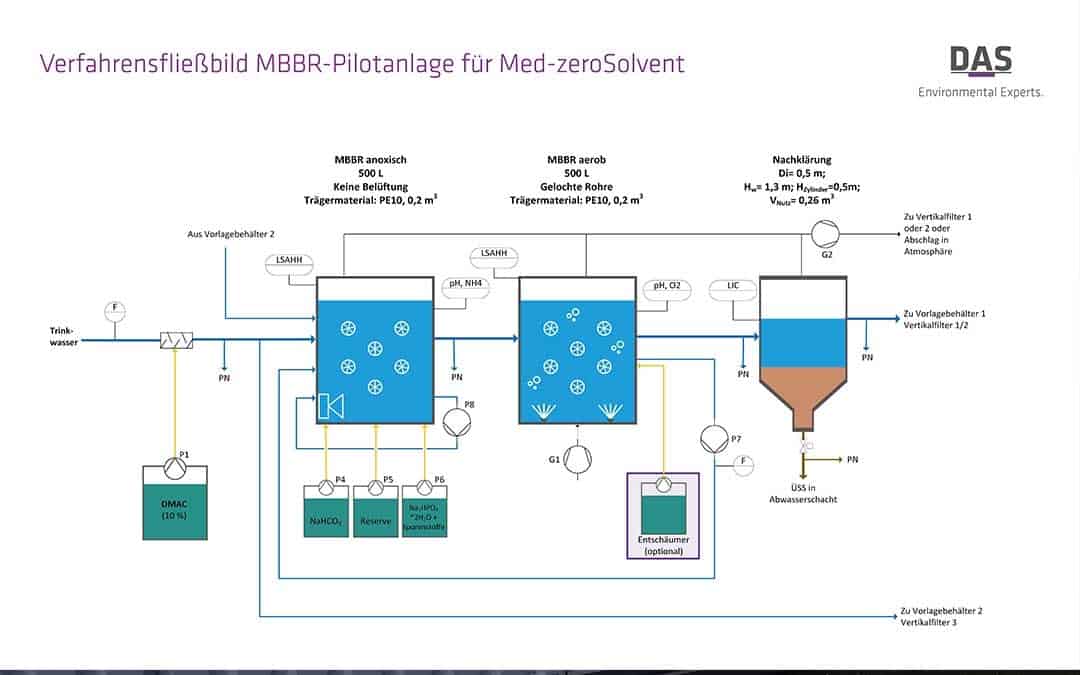

- (Waste) water treatment and recycling

Pollution Abatement Facility: The Combined Exhaust Gas Cleaning and Wastewater Treatment for the Solar Industry

Cleaning and rinsing, cutting and sawing, pickling, texturing and coating, right through to cleaning the fab — in the solar industry, various highly contaminated waste gases and wastewater are produced along the process chain surrounding the processing of silicon. Fine dusts are produced, as well as highly alkaline or acidic waters, which have to be treated. The removal of PEG, fluoride or ammonium from the water may also be necessary, depending on the process. In addition, ultrapure water with high requirements is needed in production.

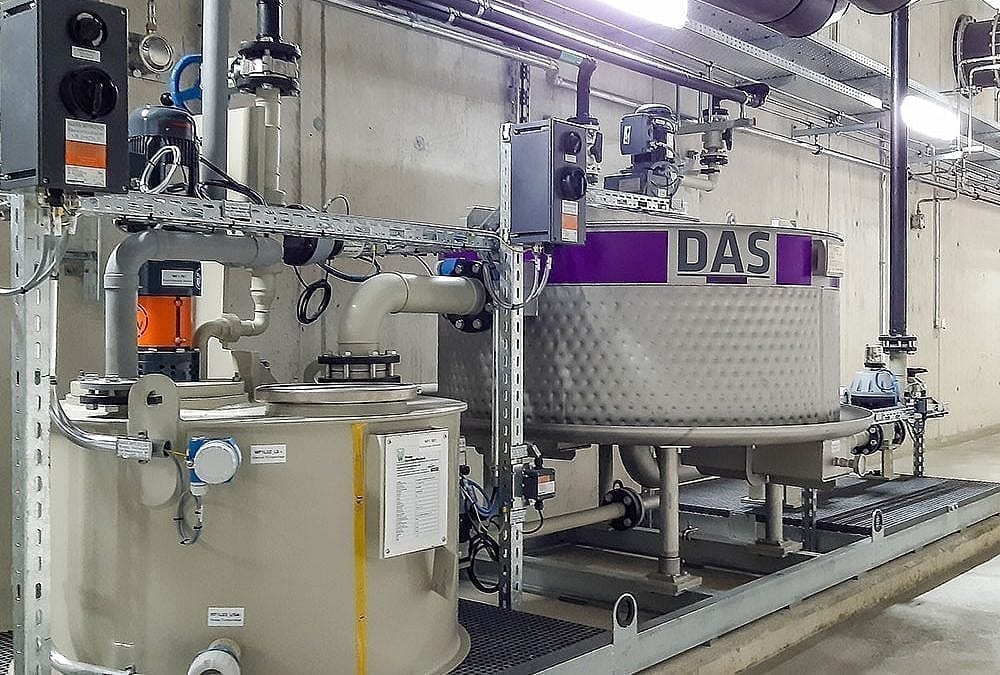

With the Pollution Abatement Facility for Solar Fabs (PAF) DAS EE offers a holistic plant from one source, which is specially adapted to the combined waste gas and waste water treatment of production facilities in the solar industry.

Your Advantages

- Integrated waste gas disposal plus water and waste water treatment

- Safe, reliable, cost-efficient

- Globally proven references

Cost savings thanks to water recycling - Removal of fine dust and aerosols

- Scalable from laboratory applications to gigawatt factories

- Efficient use of chemicals thanks to coordinated systems

Application Areas

- Waste water treatment after exhaust gas cleaning

- DI water treatment

- Treatment of washing and rinsing water